Add to Cart

FTTH Invisible Fiber Optic Cable G657 Transparent Sheath Indoor Wiring 0.9 1.2mm PVC

In the FTTH project, the end user indoor wiring is the most load-bearing, and there are many factors need to consider, such as ensuring line safety, indoor aesthetics, and facilitating construction. Therefore, invisible optical cables emerged.

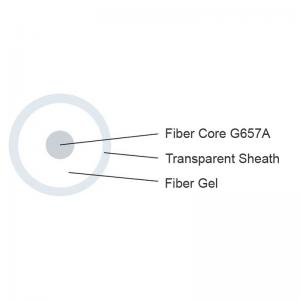

Invisible optical cable is the abbreviation of transparent tight buffer optical fiber cable, which is composed of G657 optical fiber, fiber gel and transparent tight buffer sheath. Whether the outer layer needs to be covered with hot melt adhesive or not was decided by the real application requirements. Each layer is extruded step by step using extrusion technology. The diameter of invisible optical cable without hot melt adhesive is 0.9mm, and that of invisible optical cable with hot melt adhesive is 1.2mm. Invisible cable sheaths can be made of PVC or nylon materials. Conventional invisible optical cables are made of PVC material, but if there is a higher requirement for hardness, nylon material can be chosen, which has higher hardness and tensile strength.

The use of invisible optical cables is an application where users do not accept the use of drop cable or solve the problem of difficult entry for users, especially in old residential areas and office spaces. The fiber used is G.657A fiber with a minimum bending radius of 5mm. When laying, there is no need to drill nails, brackets, holes, or pipes at the approach, which can damage the original indoor structure or cause safety hazards such as cable sagging and falling off due to discontinuous laying. At the same time, because the cable is almost transparent, it will not affect the indoor aesthetics. The construction method is simple, and only handheld heating installation tools are needed to complete the laying project.

Features

Technical Parameters

| Cable Type | Figure-8 type | Micro type | |

| Outer diameter | 2.0*3.0mm | 0.9mm | |

| Weight | 10kg/km | 1kg/km | |

| Color | Black, white | Transparent | |

| Tensile strength | 200N | 50N | |

| Min. Bend radius | Dynamic | 20mm | 5mm |

| Static | 10mm | 3mm | |

| Transmission loss | 1310nm | ≤0.4db/km | ≤0.25db/km |

| 1550nm | ≤0.4db/km | ≤0.25db/km | |

| Working /Storage temperature | -40℃ ~+70℃ | ||

Operation Steps

1. Prepare the optical cable to the installation tool

2. Use wire stripping pliers to clamp out a skin gap without damaging the fiber optic.

3. Use your fingernail to peel off a 0.9mm outer skin from the skin gap. After peeling, use a cutting knife to cut it flat, and clean the fiber optic cable and end face with alcohol cotton.

4. Install along the threshold or skirting line, assemble connectors or weld on site.

Almost invisible after completion.